Indoor

Big Ass Fans’ stylish, innovative airflow solutions bring comfort to every corner of your home.

Outdoor

Offering the world’s most advanced fans, Big Ass fans are built to endure the elements and bring comfort to your favorite spaces.

Speclab

Take the guesswork out of comfort and see the benefits of a Big Ass Fans solution before you buy with our proprietary computational fluid dynamics (CFD) software - SpecLab®. Visualize and quantify the power of our fans with ease, making your purchase decision a breeze!

Digital Toolbox

Get the facts you need to make the right choice for your business with the Big Ass Fans Digital Toolbox. Applications range from design guidance and product specifications to employee productivity and energy savings calculators—all with clear results that are easy to understand and share.

Industrial

Agriculture

Automotive

Aviation

Commercial & Public Spaces

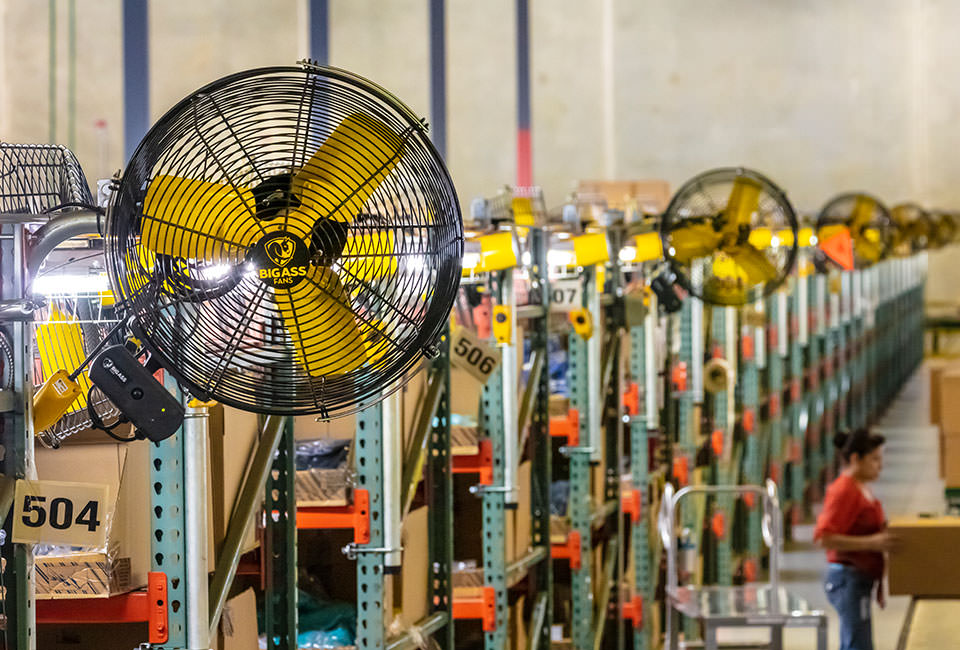

Distribution / Logistics

Education

Fitness

Government

Manufacturing

Don't let heat and harsh conditions slow down your manufacturing process or jeopardize the safety of your workforce. The solution is a Big Ass fan.

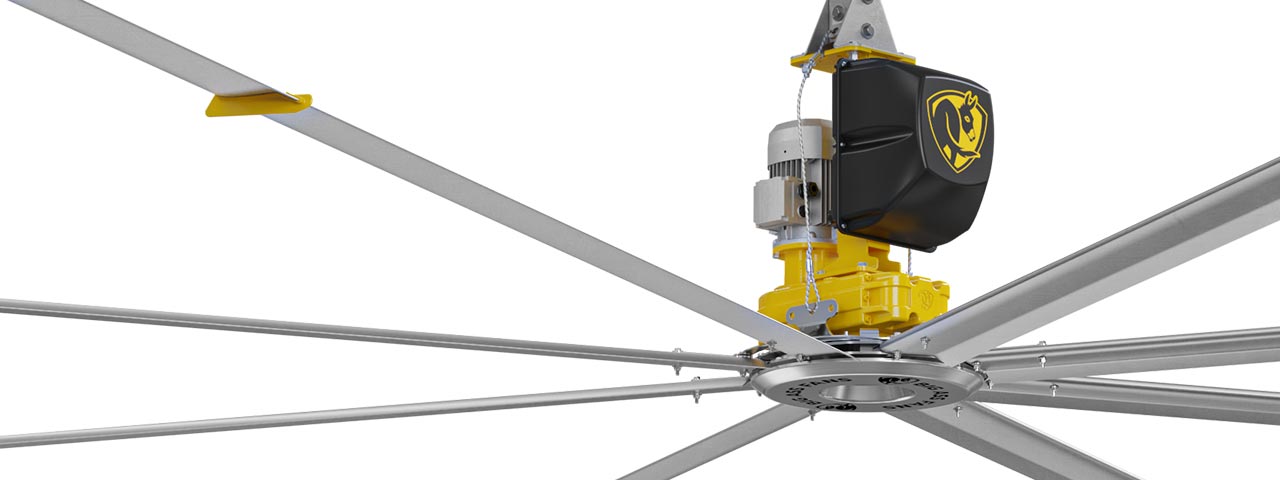

Large Overhead Fans

Powerfoil® X4

Powerfoil D®

Powerfoil® 8

Basic 6®

Essence®

Small Overhead Fans

i6®

Haiku®

Haiku® L

es6®

Directional Fans

Sidekick®

AirEye®

AirGo®

Black Jack®

Yellow Jacket®

Pivot

Destratification Fans

Hornet

Case Studies

Whether you are looking to cool a large industrial space or a small personal area, our fans have been proven to deliver reliable and effective cooling solutions.

Speclab

Take the guesswork out of comfort and see the benefits of a Big Ass Fans solution before you buy with our proprietary computational fluid dynamics (CFD) software - SpecLab®. Visualize and quantify the power of our fans with ease, making your purchase decision a breeze!

Digital Toolbox

Get the facts you need to make the right choice for your business with the Big Ass Fans Digital Toolbox. Applications range from design guidance and product specifications to employee productivity and energy savings calculators—all with clear results that are easy to understand and share.